As I have said before on the blog, most parts from the engine towards the rear of the vehicle are Land Rover, but engine based parts are either Isuzu or available from Land Rover Australia only. A search for these takes you to either Landybitz or KLR in Australia.

My friend and Perentie “partner in crime” Darren was having a box shipped from KLR Australia, in which there was some room……….

So, I ordered up a Water Pump, Thermostat and gaskets, and a few other bits that I may need in the future. There was still room in the box, so I added a rear disc brake conversion kit for the rear axle – more of that in another post.

From inception to arrival this took months, mainly down to KLR being useless administratively. Once the box was shipped, it arrived in just a few days.

So now it was time to tackle the job that I had been planning for nearly year!

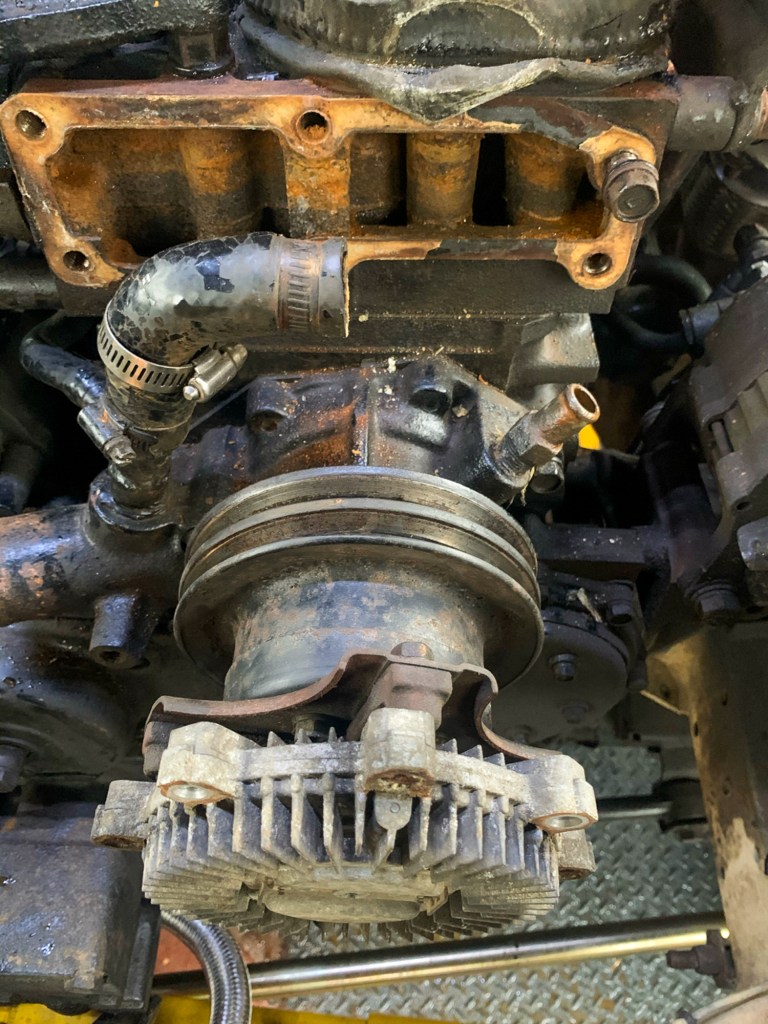

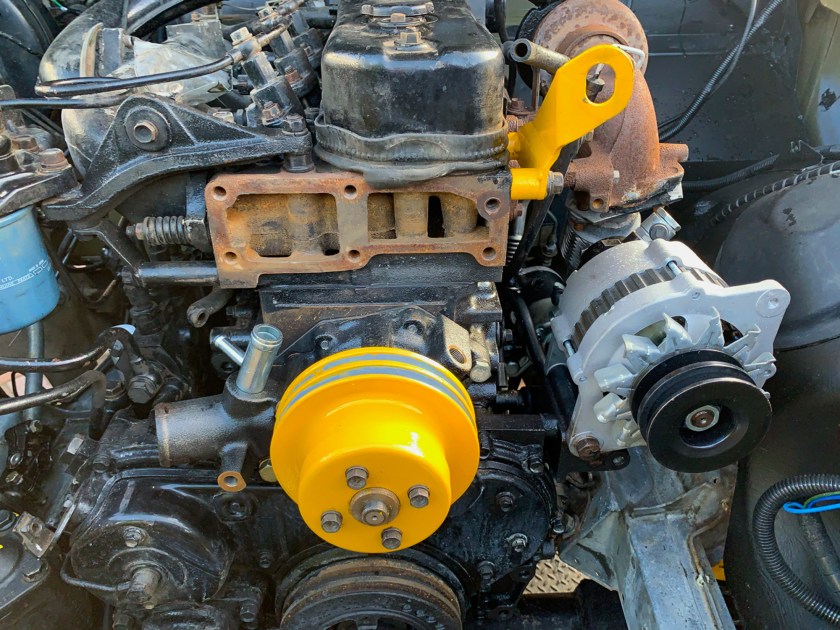

I removed the bull bar and the front panel in front of the radiator for improved access and then the radiator, viscous coupling, water pump, thermostat and the housings for the thermostat and water pump. With everything stripped back, I also removed the alternator and starter motor, replacements for which I already had. All of the water pipes came off as well as they were all past their best.

The heater box came out as well as it was in a very sorry and rusty state.

So long story short, all of the old parts and the heater box casing were stripped back and repainted. A new matrix was purchased for the heater along with bulkhead seals. I am not sure that this will make much difference as the heater on the Land Rover is archaic to be polite! But a least it reduce the possibility of a future leak as access to it is a pain…

The radiator went off for a re-core with a more modern efficient core with Paul Slack ,who provided an excellent and efficient service. This is his e-mail – paulslack55@btinternet.com.

The Radiator was as I thought from a Land Rover V8, but with the inlet and outlets switched around.

Everything went back together without “drama”; believe it or not…………..

The only delay was that I wanted to replace the corroded bolts that held in the Water Pump and Thermostat housings, together with the barbs that the heater hoses attached to. It turned out these the threads were a fine thread metric and my usual supplier did not stock them. Again, e-bay to the rescue……….

The viscous fan was not re-installed though, this was replaced by a Revotec Electric fan which I have mentioned previously; the wiring for which was already in place.

Replacing the hoses was more of a challenge than I expected though, as nothing was standard Land Rover. I measured everything up carefully and ordered what I needed in silicon. This included water and oil pipes that go to the alternator for cooling and lubrication.

Some of these pipes fitted not problem although the ones for the alternator were tricky to fit because of the room that was available.

The main problem was the top and bottom radiator hoses. The top on right had to be cut to fit the sensor for the electric fan which made the length of the hose very short. Because of the bend, the silicon (which is less flexible than I thought) was under tension and just would not stay in position. A similar situation for the bottom hose on the left, which has a “T” so coolant can go up to the expansion tank, so that the coolant level can be checked easily.

Its did not help that the ends of these hoses had different internal diameters which necessitated a reducing piece.

Eventually after trying many different options I abandoned silicon (for the tricky bends) and took myself over to Paul Light Land Rover in Hordle (again!) with the original hoses which had the correct bends.

Paul, who is forever helpful, went through his stock and eventually found some hoses that had similar bends to the that I needed. I cut these down and eventually ended up with a complete cooling system.

In retrospect, I could have ordered these from Australia where they are available. but at the time I wanted to go silicon – the best laid plans.

I refilled the system with coolant and fired up the engine to check for leaks and to see if the new fan kicked in at the right time. The vehicle ticked over on the drive with no leaks which was a result. It was not getting hot enough though for the fan to kick in in. It was getting late, so I decide to wait until the next day to take the car for a drive to get the temperature up to. proper working level.

I did not know at the time, but that was the beginning of another challenge