One thing always leads to another, in this case it was a Dog lead……

We had always planned to get another Dog following the sad demise of Benita’s Bassett Hound “Sir Henry” a couple of years ago, it was just a question of choosing the right time.

Well, we were waiting in the garage for a small job to be done on Benita’s Audi TT back in January – to pass the time I picked up an 8 year old copy of “Pets Monthly” that was sitting in the pile of old magazines that you find in these places and started to read out the lead article on adopting a retired Greyhound.

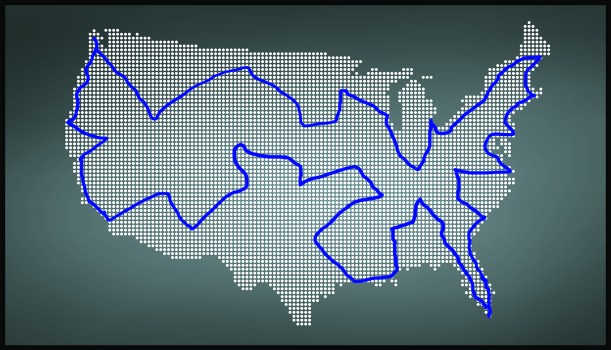

Well after a few paragraphs it occurred to us that this could be the ideal dog, generally quiet (they don’t tend to bark), good natured, require surprisingly little exercise and as an added bonus, they sleep for most of the day. What better breed for 48 States of Grey!

After some thought, we visited the Greyhound Rescue centre in Surrey where a beautiful female introduced herself to us, after a short walk we decided that this would be our new Dog. A couple of weeks later, after the formalities had been completed, we collected “Ettie”. It was on the first day of lockdown; it was quiet on the roads………

As previously mentioned. we don’t now know when we will get to the States – probably once everyone has been vaccinated. Although still planning for this long term, we will probably do trips nearer to home next year, maybe Ireland, Scotland and maybe Europe. We have my Dad and friends who has offered to look after Ettie when we go to the States.

So it was not long before Benita suggested that Ettie might join us on the the more “local”trips. Initially, I was not convinced – there is not much room in a Land Rover for us and a reasonably large Greyhound. After some thought and knowing Benita’s penchant for a trailer, I suggested just that, as a solution………

My thoughts soon turned to a Military Trailer – a Penman would look good with the Perentie which already has a NATO Hitch…………A quick search turned up the usual rot boxes and some unused examples at the Military Auction houses. I didn’t want another project and knew that I would need to build some sort of weather proof structure over the trailer, if Ettie was going to sleep in there and we were going to use it to store extra gear (another advantage of a trailer, I have to admit).

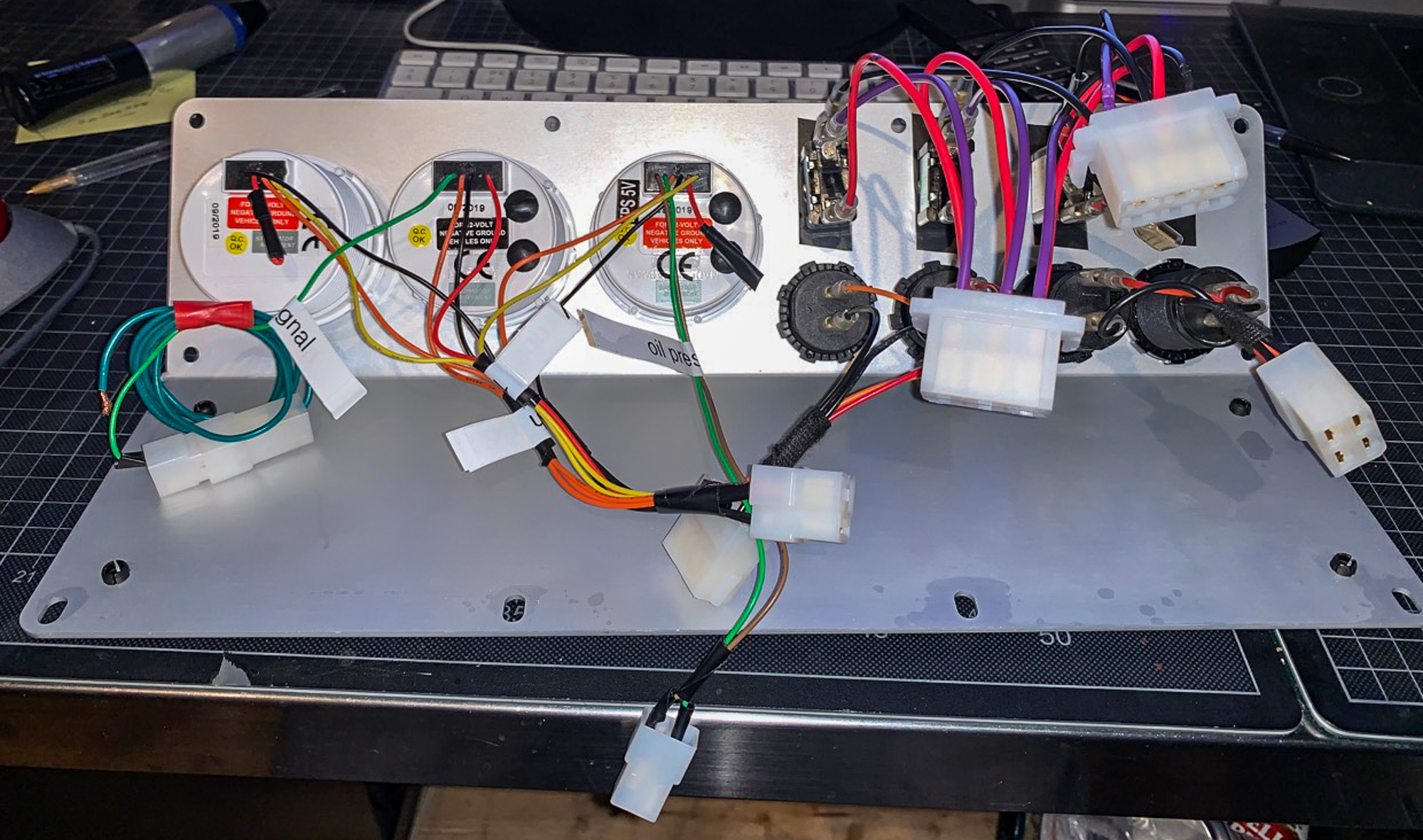

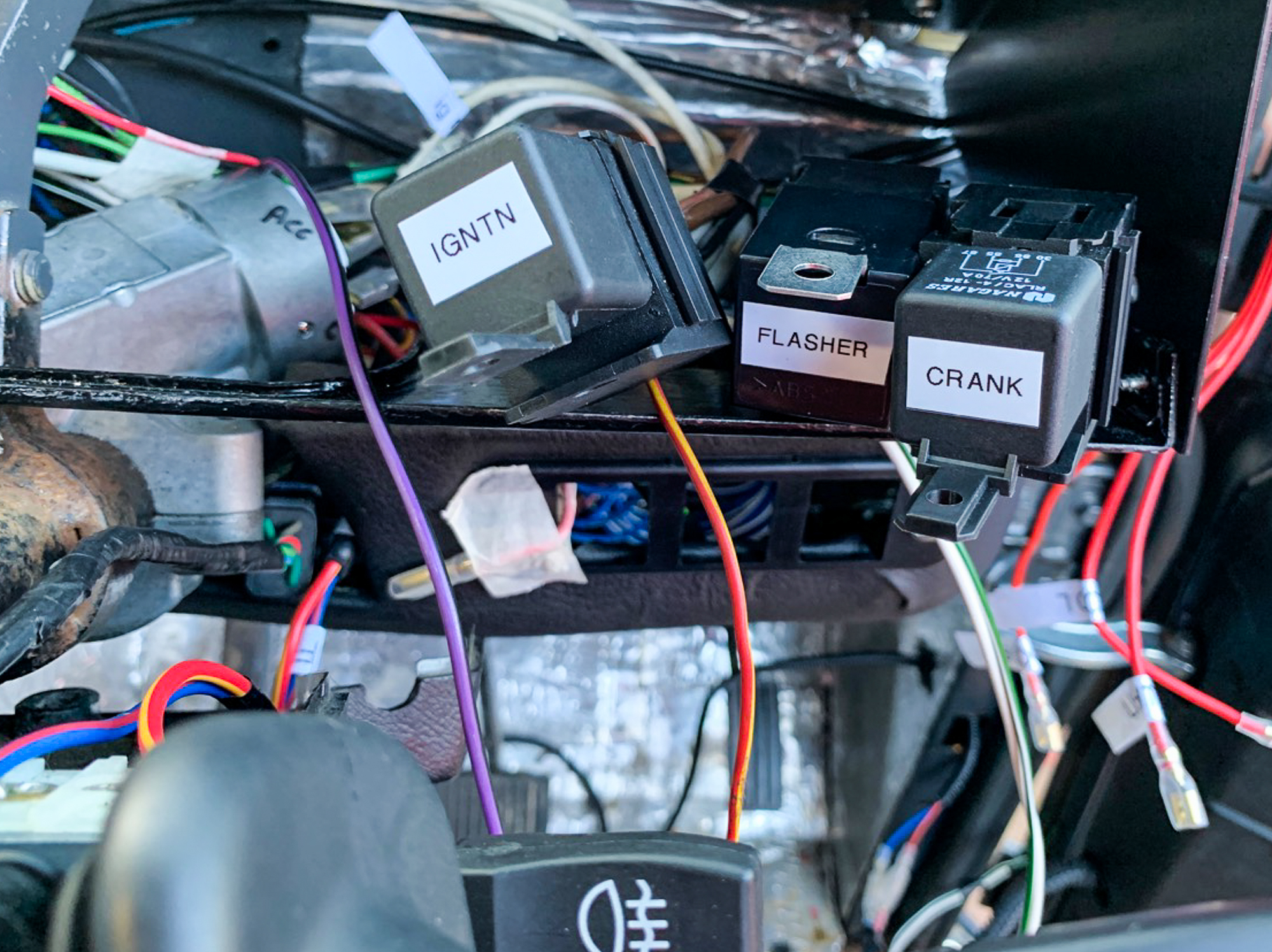

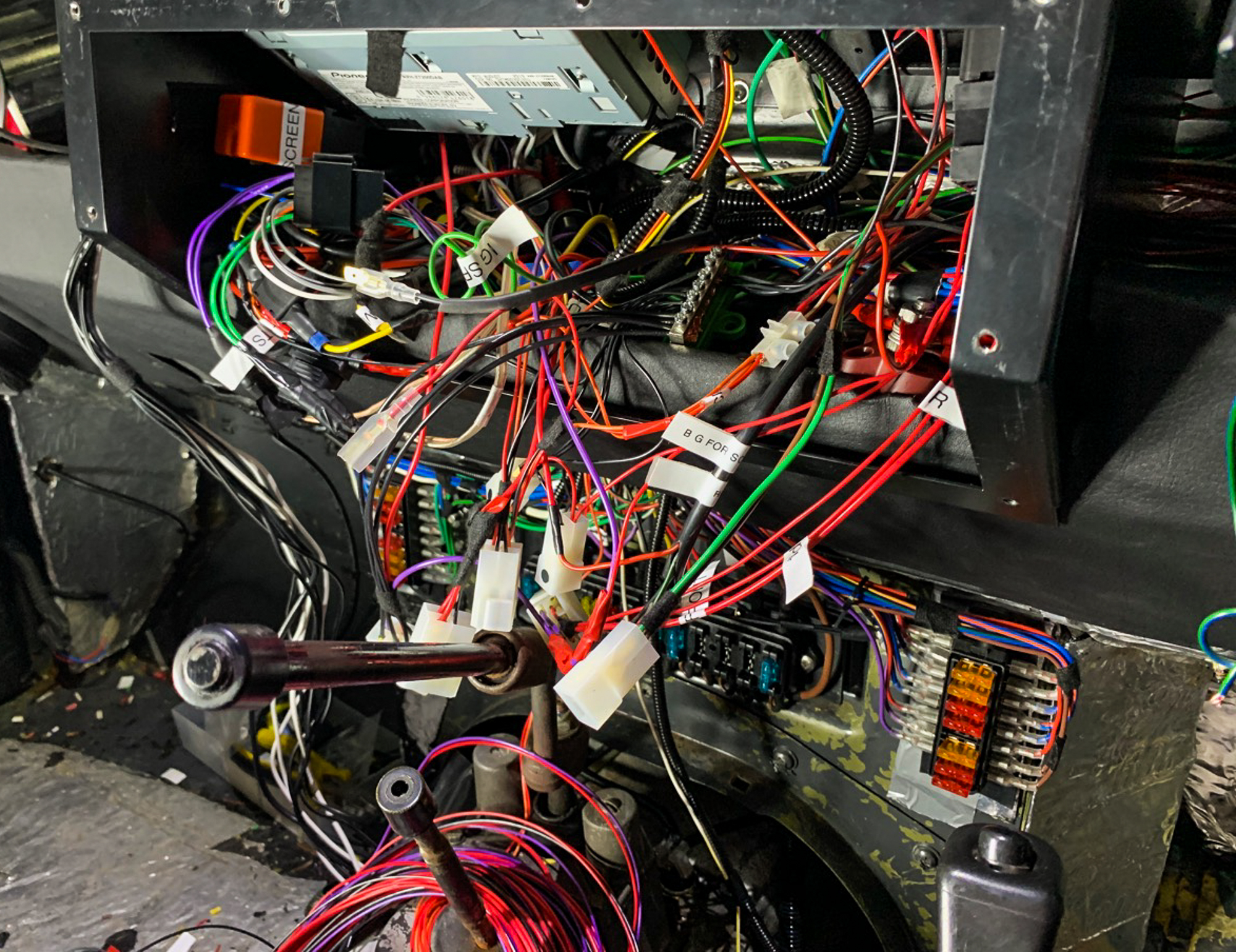

Then on everyones favourite auction site, a converted Penman turned up. The seller had bought it new at auction, painted it grey (Perfect!), built a weather proof top, fitted some cool wheels, racked it out and put in electrics – as a bonus it had a Tuff-Trek roof tent…….A deal was done and the sellers, a lovely couple from South London offered to deliver it too us – by now we were reaching the end of lockdown and they were desperate for a trip to the coast – a Win/Win situation.

I must admit, it was a bit bigger than I thought it would be, but the build of the trailer itself is astounding which is not surprising as it was designed to be thrown out of aeroplanes, as was the Perentie.

We have tested the tent which is a doddle to put up, it also comes with a rear awning which is great for keeping dry during rain showers when working out in the front garden. For now it is being pressed into service as a parts/tool store, it has saved me hours of walking back and forth to the shed for bits!

Hmmmm….shelter when working on the car on the drive – this leads me to the next post.