Well, I have mentioned this before, so just a quick post; promise……..

All of the dash wiring has been just about completed for a while, apart for the connections for the Rev Counter and Oil Pressure Gauge, and…………a reliable feed for the instrument lights in the main dash.

The original instruments were in poor condition and I tried to fix these up. In a nutshell the sleeve that the bulb holder fits into was broken on a couple and the green plastic diffuser that sits inside was melted, due to someone in the past fitting the wrong wattage bulb. As the lights were so dim, people upgraded the 2W bulb to a 5W – but this just melted the whole fitting after a while. The original bulb holders are impossible to get so I just made do with a later style fitting; these did not really work as the LED lamps that I was using did not fit correctly and the lights kept turning off!

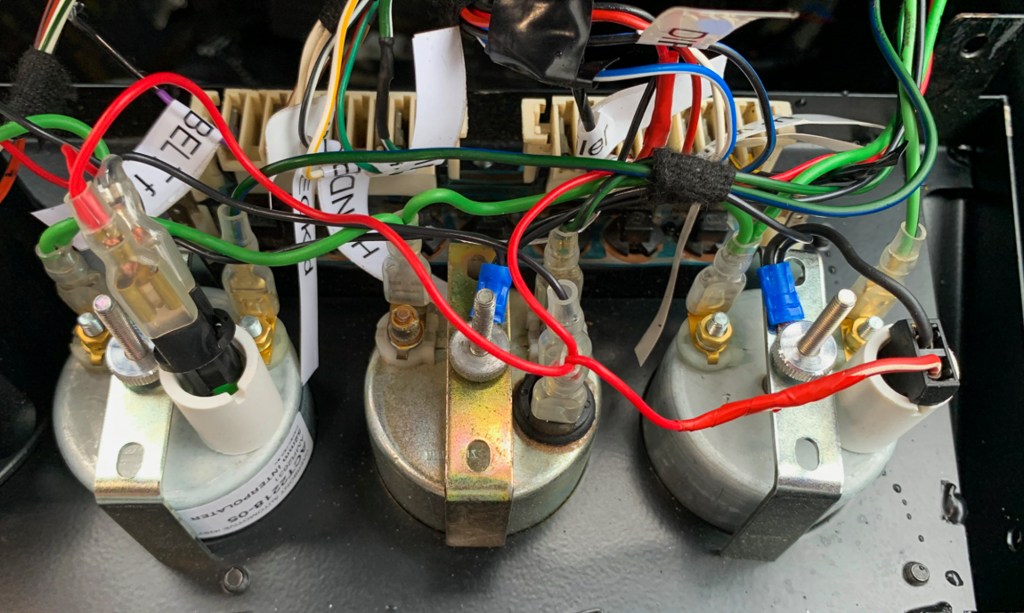

So when we we did the re-wire, we made up a wire loom that connected everything together, so that it worked. Relatively simple; each needed an ignition feed, an earth, and an earth and 12v feed to the instrument light itself. Also the feed from the sensor for the instrument itself, so from the water temperature sensor and the fuel tanks.

So in the end I just got a new water temperature gauge and two new fuel gauges, as I wanted to be able to monitor levels on the second tank once it was installed. Whilst the new gauges came with the sleeves that the bulb holders fit into, thats all you got. No bulb holder as these were part of the loom.

So I ordered a dash loom that Auto Sparks lists on their web site, that was in June and it arrived in late September due to Covid issues as all their looms are made to order. So I was ready to complete the job……………

Well the loom did not quite match what I wanted, a couple of bulb holders that obviously were for a speedo head that I did not have and no ignition feed linking the instruments and a couple of other 12v power leads that, in retrospect were for the clock that I had removed and replaced with the second fuel gauge. The positive was that I had the bulb holders that I needed, so I just cut these out with the respective earths and left the ignition feeds that we had made earlier (just like Blue Peter!).

So all done and ready to test…then I realised that the bulbs were different………..So a trip back to auto-leds who are extremely helpful and efficient, and I got these. Cool white as the new instruments has the green diffusers in situ..

All done, at last; another tick in the box.

Note:

After fixing the dash panel back into place, which was a real pain; because it was all new and none of the fixings lined up correctly. One of the instrument lights did not work. So I had to undo it all again. It turned out that one of the bulb holders had come out of the sleeve on one of the fuel gauges; they were not the best of fits, so it must have come loose when I was getting the dash back together. Anyway, they are now secured with some insulation tape to make sure it does not happen again.