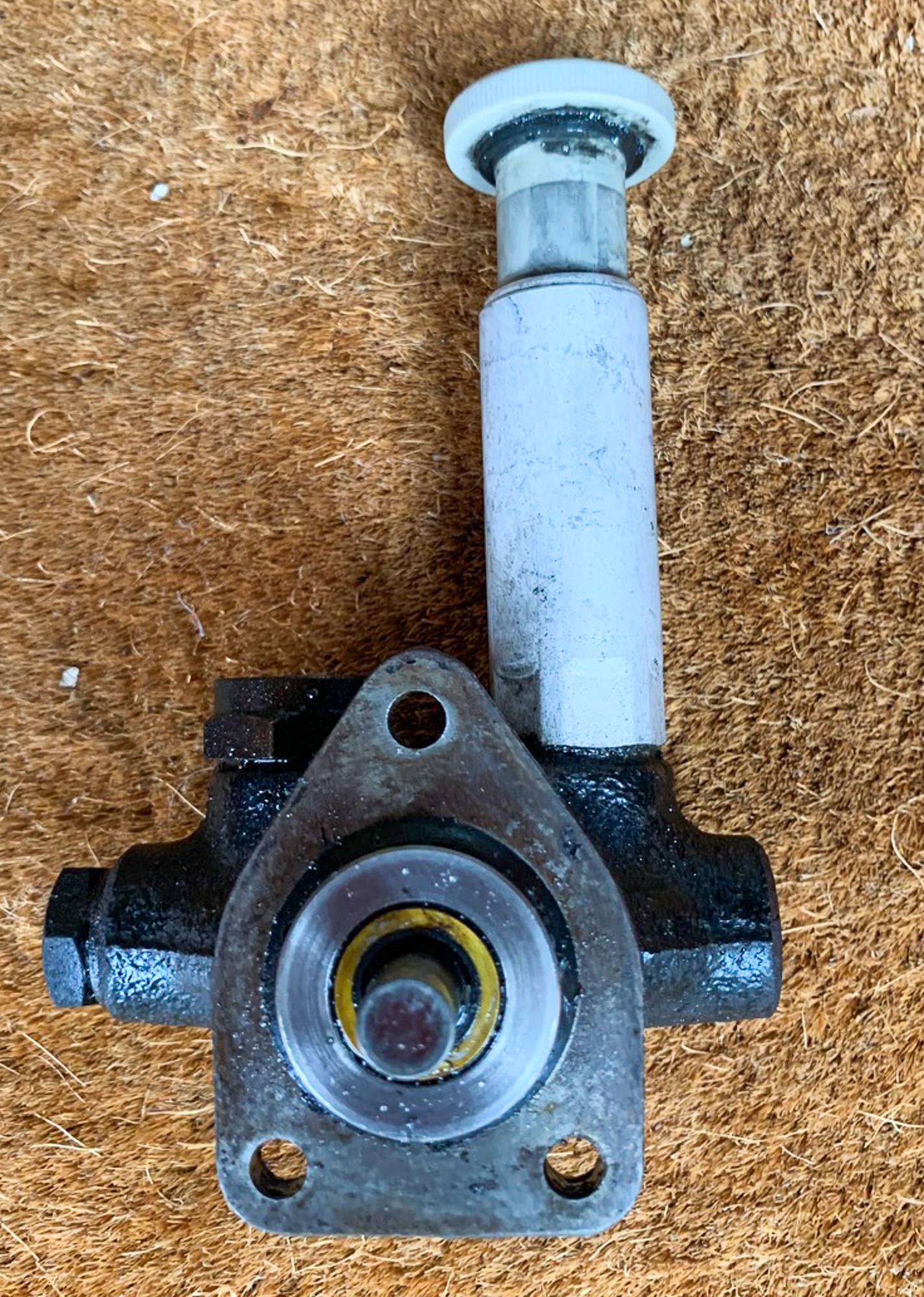

Well the fuel pump has returned and is looking good!

Old and newly re-built above, it is almost a shame to put it back on the vehicle.

The service from Darwen Diesels who did the work was fabulous. I posted it off with an old fashioned letter. They called me to confirm receipt the next day and to say that it was going straight into the workshop. Day 2, I get a call saying that the job was done and asking for the grand sum of £65.18 in return, that included postage and a pack of washers. Day 3, I have it back.

Anyway to work and back on the vehicle it goes, easy job, bleed the system again, jump in the drivers seat to fire it up and – Yep, churning and no firing Grrrrrr.

By chance my friend and Land Rover guru Darren was due to call in that morning as he was passing; he arrived at the end of the Grrrrrrrr. After a quick resume of the situation we tried to start her again, Darren reached under the bonnet and bingo we had a Perentie with a running engine. So, what was the problem.

Well, Darren had manually opened the throttle which was not opened fully, thus restricting fuel; so why was this?

In Europe and some states in Australia Diesels are required to have an automatic fuel shut off, rather than a simple manual cable – the shut off is controlled by an EDIC Actuator which is controlled via a relay by the ignition. S0, the actuator was not opening the throttle wide enough.

I started to follow the cables back from the actuator to see if a problem was obvious. Most of the wires were covered in insulation tape which was now beginning to unwrap itself, including a relay which I assumed controlled the actuator.

Give it a squeeze and the actuator works, so the badly made and oxidised connections were the crux of the problem as a quick re-wire of the connections proved correct.

Darren at this stage points out that the Glow Plugs are not wired up – the Ozzies don’t bother – don’t need em Mate!

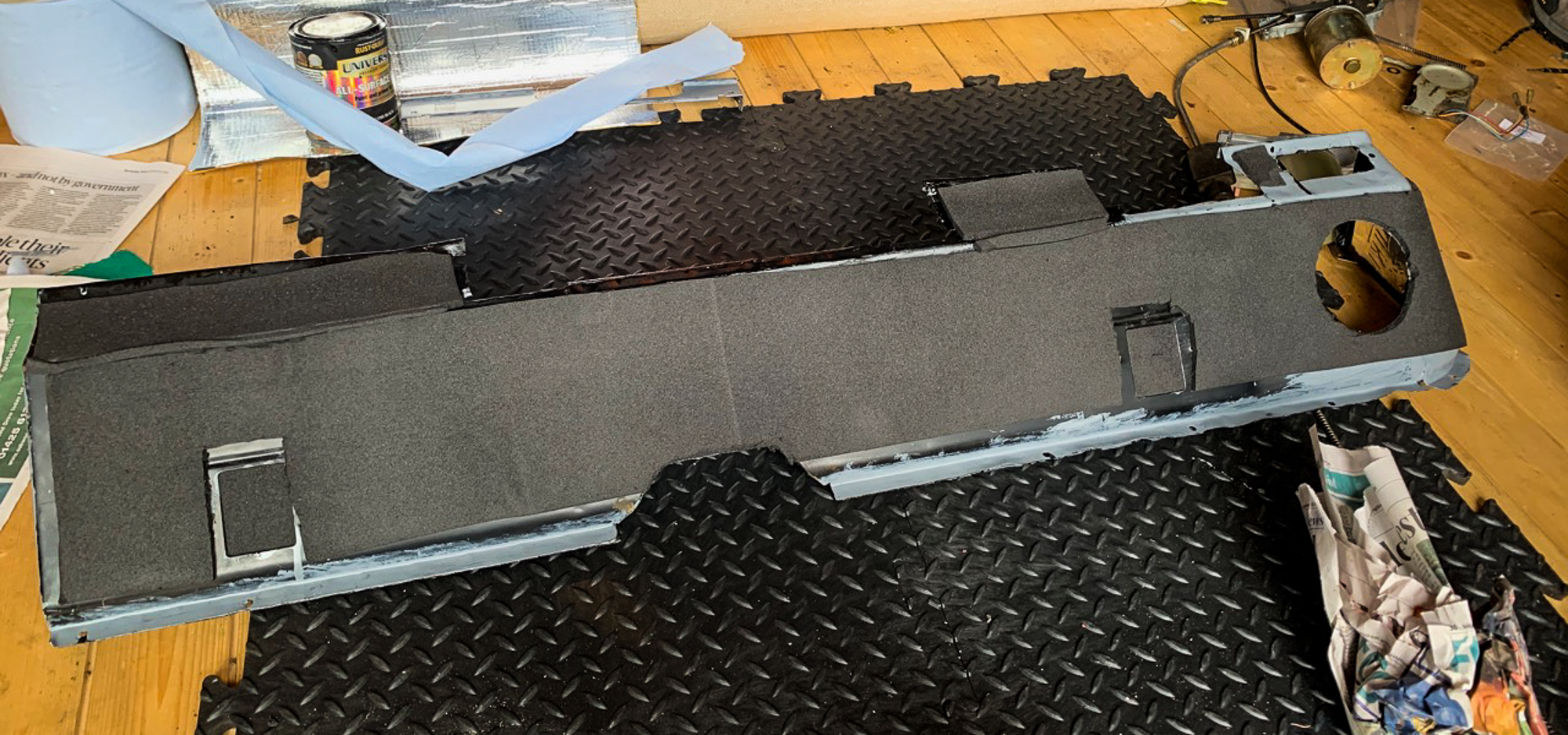

If you have read previous posts you will remember from “Can you smell Burning” that this is not the first wiring issue that has turned up! So I spend an afternoon tracing and and unwrapping cables finding lots of loose ends, some of which are live, and dodgy connections as I go (most just wires twisted together). I trace the ignition wires to behind the dash and find a similar story. Digging deeper, I now realise that it is only the EDIC and the ignition that is running through relays and that only about 8 circuits are fused, despite fuses being present visually in the fuse box. Six of those were the lights Full Beam, Dip Beam and Side lights………Left and Right – Thats safe then!

The discovery of a few cables that were starting to melt made me realise that this was not going to be a quick fix.

I could not risk even using the Perentie given my discoveries, let alone add the additional circuits that would be needed to take her to the States and re-wiring the rear lights was already on the job list.

With no off of the shelf loom available because of the mixture of Land Rover and Isuzu wiring it would be re-wiring without a safety net.