Phil and I worked together for about eight days on the car through January and February. We tried to get “rain free” days by carefully checking the weather and to a point we succeeded in achieving that. It was cold, especially first thing in the morning and at the end of the day, but overall the weather was not that bad. I would get on and do bits of preparation on the days that Phil was not there.

I wanted to get on rather than wait for better weather as I had planned to get on and landscape Benita’s garden in the early Spring and I had the time. Believe it or not, we were still unaware of the impact that Covid 19 would have on the way that we work together. We all got on well and Phil stayed over a couple of nights to save the long drive back and forth to his home. Benita who is a great cook would sort dinner and we would enjoy a couple of glasses of wine and some music as both of us play guitar. Those times now seem so far away as restrictions prevent us from enjoying the simple things in life such as each others company, conversation, jokes and music.

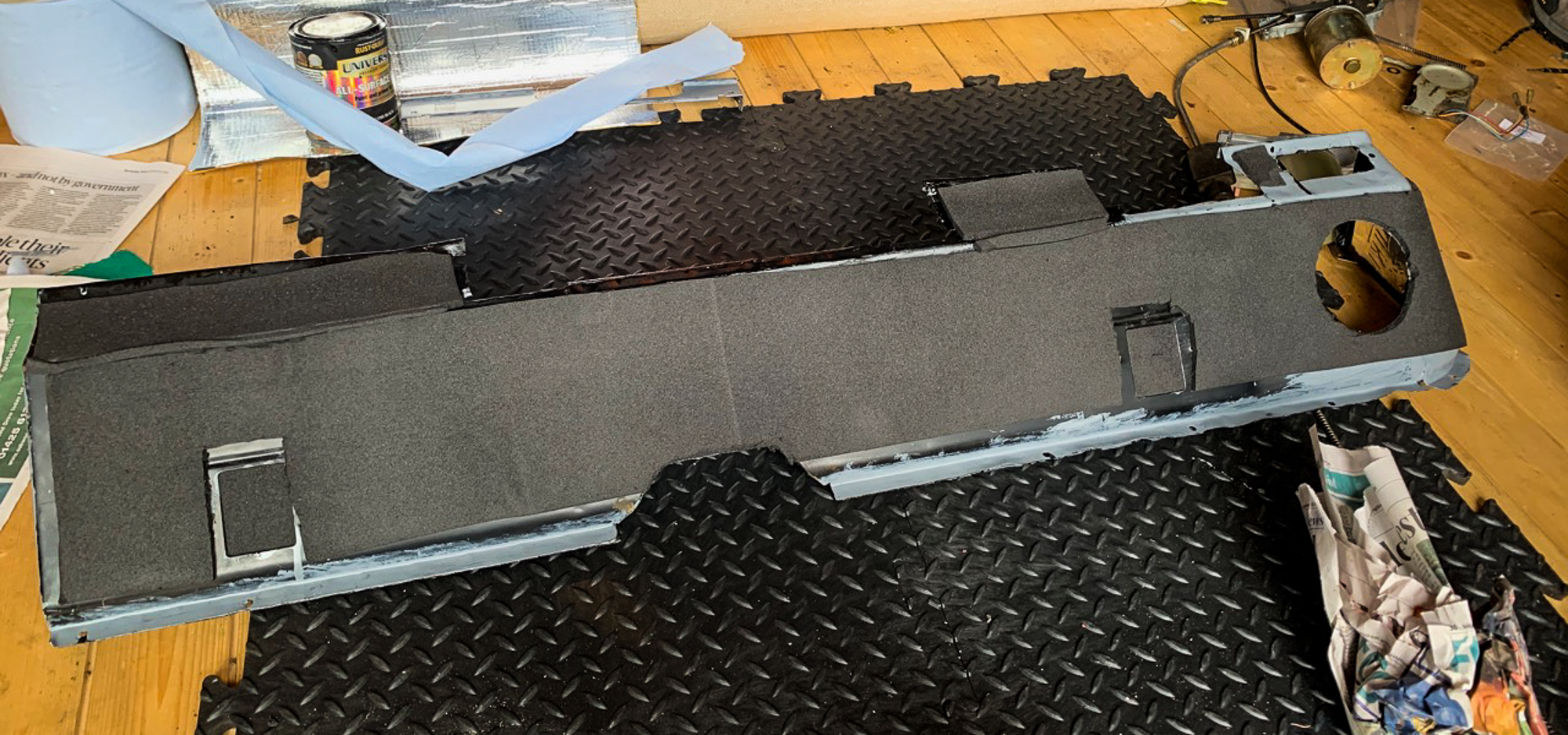

The Perentie is a very basic car when it was in service with the RAF and ours was fitted with an early TD5 dashboard when it was imported, in order to give it a proper key ignition for example.

I wanted to upgrade the dashboard so that I could use the better made Raptor Engineering dash binnacle in front of the driver. Raptor make a steel binnacle and front dash panel which replaces the plastic Land Rover one, you just need to source the screw in instrument light cluster and connections to the loom. I managed to find one on e-bay locally and drove to the other side of Bournemouth one evening to collect it. Ironically I put some of my spare parts on e-bay a few weeks later and they same guy turned up at my door after having purchased – small world!

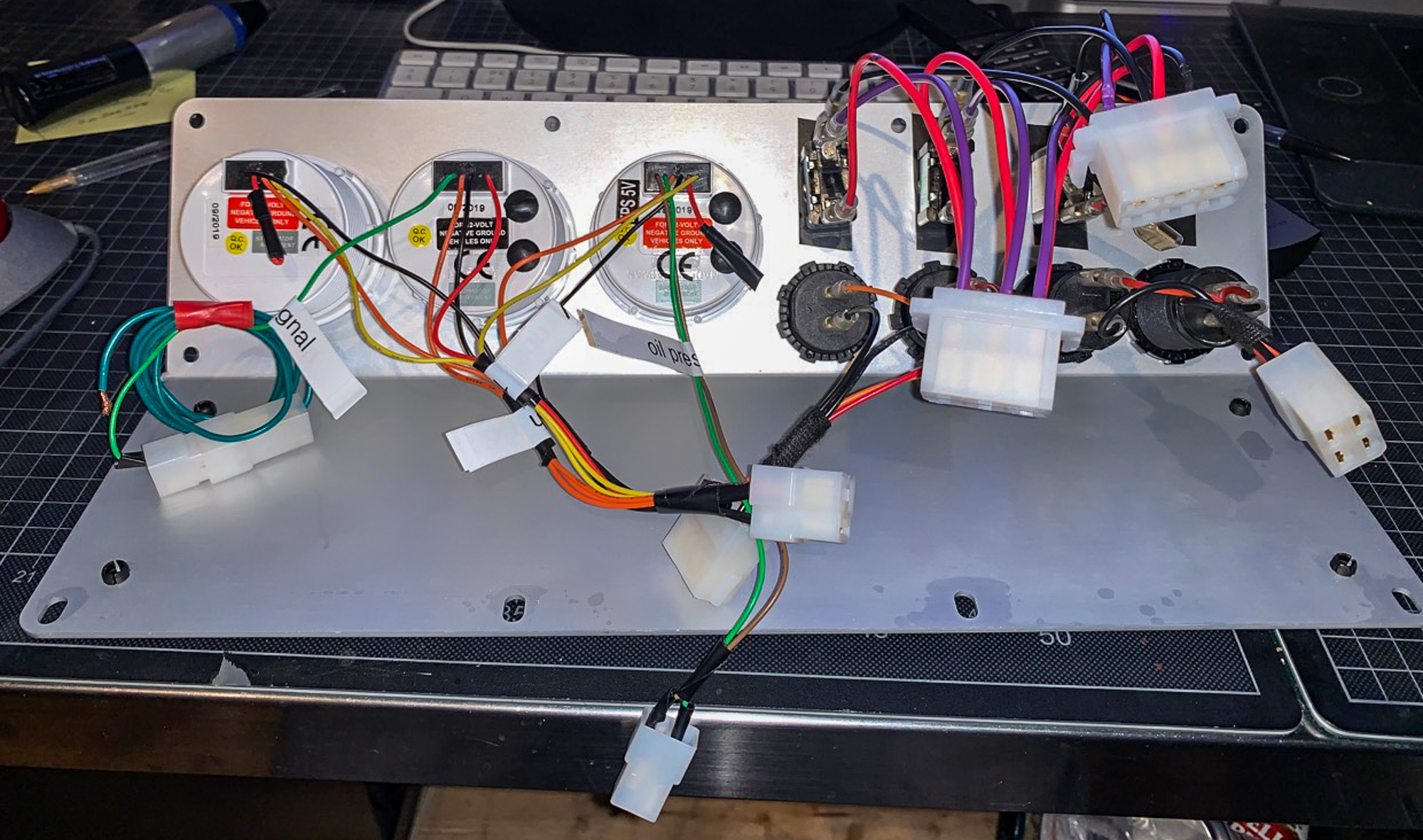

Raptor also make a centre dash with many customisation options for gauges and switches which I am also fitting.

Note that everything is wired into multi-plugs to make the removal of the bottom section easy. The small holes in the bottom of the binnacle in the top picture will house LEDs to illuminate the footwells.

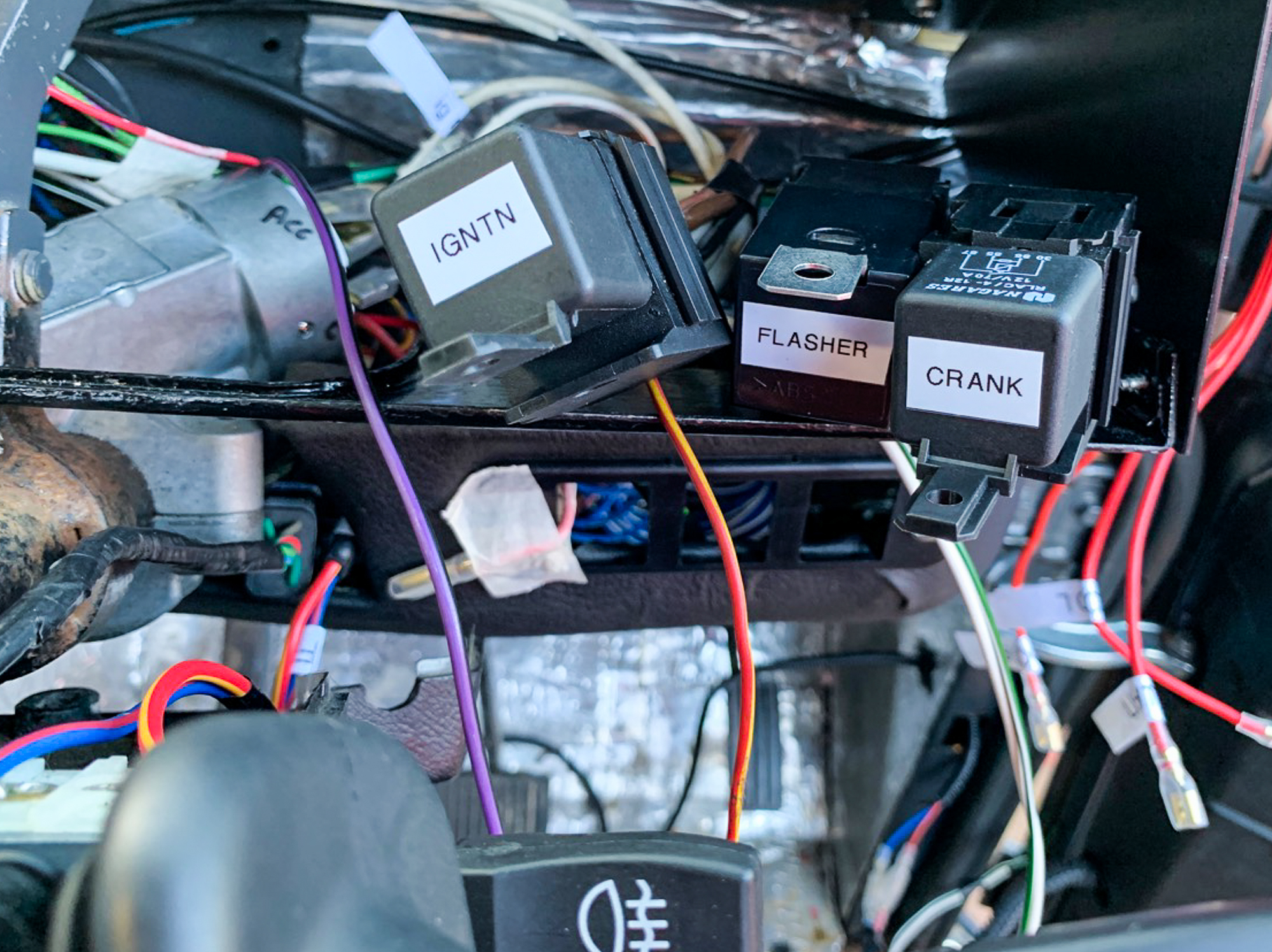

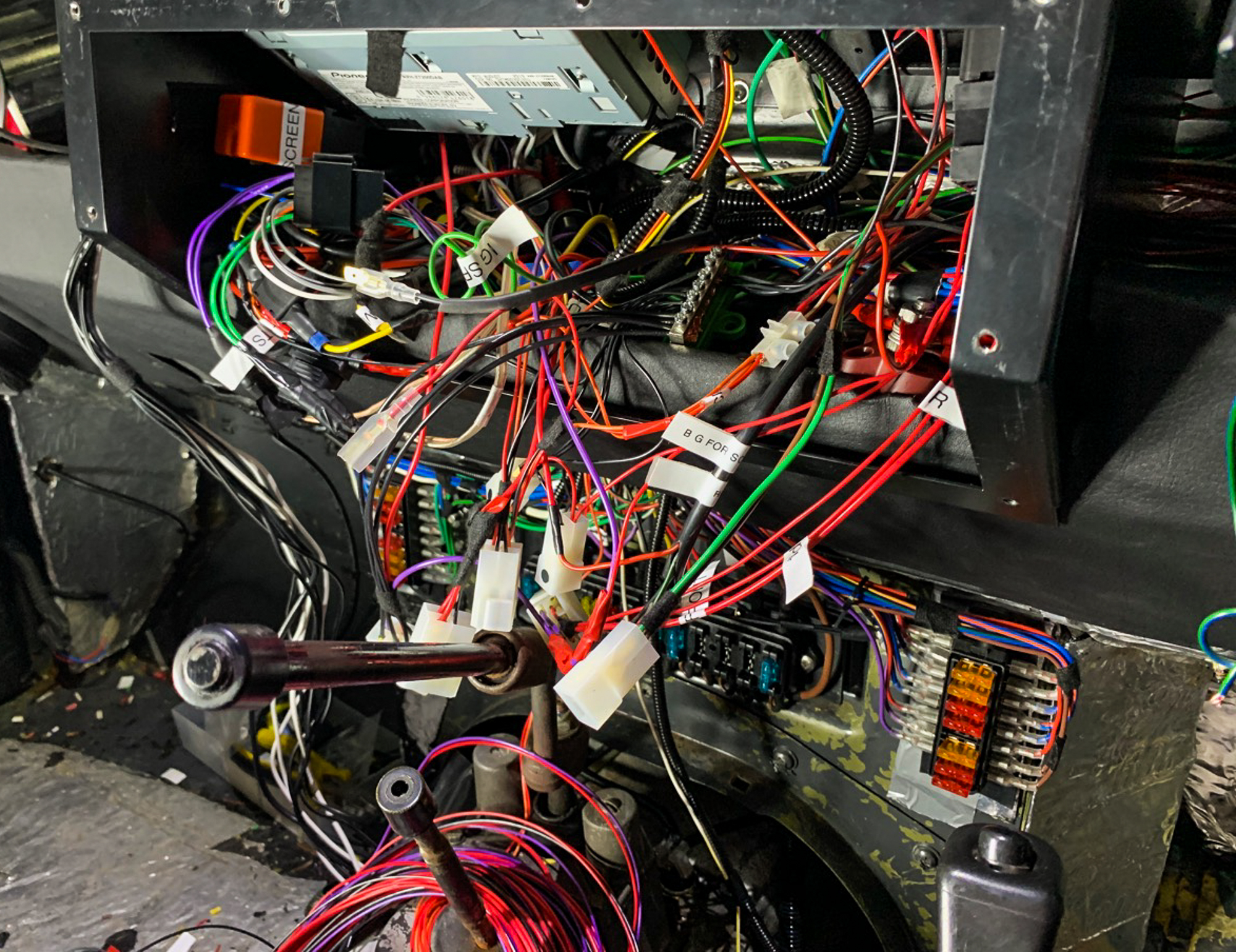

All starting to come together, lots of wires but everything labeled and I have a separate schedule that details wire colours and fuse numbers for every circuit.

At this stage all of the main circuits had been tested and were working fine. Most of the instruments had been wired up. but the speedo, fuel gauge need to be tested along with the warning lights.

But that is for another day as I have to landscape a garden and build a log cabin; and of course deal with the lock-in!

I hope everything still works when I get back to it……………